PRODUCTS

Optical Communication Applicat

-

Active Component Manufacturing

- Optical LD & PD Wafer

- Aspherical Lens and Cap

- TEC Device

- 2.5G-10G APD CHIP

- 10G PIN PD CHIP

- Transimpedance Amplifier

- Aluminum Nitride Substrates

- Alumina substrates

- High Temperature Co-fired Substrates (HTCC)

- 10G CWDM DFB Chip

- Microlens Array

- Smile Corrector

- Slow Axis Collimators(SAC)

- Fast Axis Collimators Arrays(FACA)

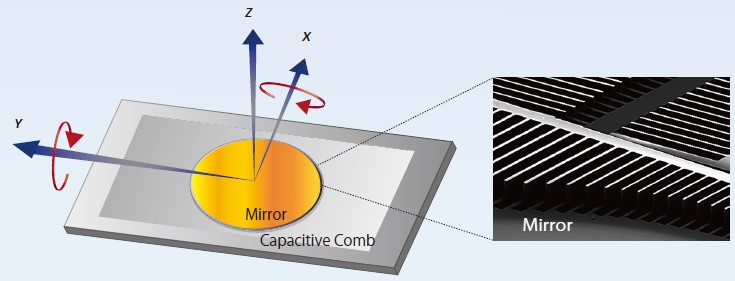

- MEMS Mirror

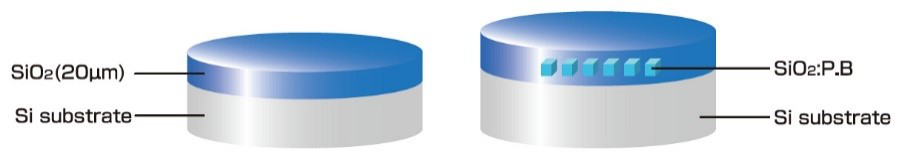

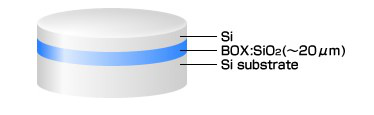

- SOI Wafers

- Super-thick Thermal Oxidized Wafers

- 25G DFB Laser Diode Chip

-

Test and Measurement

-

High Speed Qptical Transceiver

-

Optical Transport Network Devi

-

Network, Security and Delivery

-

Optical Automation Equipments

-

Passive Component Manufacturin

Industrial Laser and Optical A

-

Lasers

-

Laser Drivers

-

Controller Electronics

-

Optical Components

-

Materials

Solutions

-

BOSA Manufacturing and Packagi

-

ECDL Stable Laser Solution

-

Laser Spectroscopy Solution

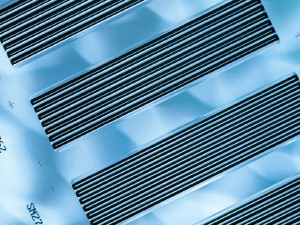

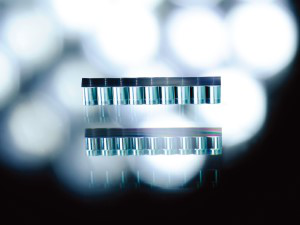

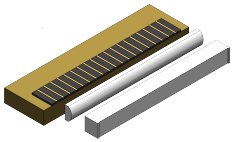

Smile Corrector

PowerPhotonic provides a range of smile correctors for laser diode bar and stack applications. These innovative products remove the effects of “smile” error on the collimated beam.

The “smile” effect, caused by CTE mismatch during solder bonding, prevents the fast axis collimation (FAC) lens being correctly positioned for all points along the bar, resulting in beams with variable pointing direction. This increases overall fast-axis divergence, and can have a severely detrimental impact on VBG locking efficiency and locking range.

Key Features

• Single optic that can reduces smile to a level that no longer affects system performance

• Monolithic design

• Fixed or custom variants possible

• Transmission >99%

• UV-fused Silica

Supplier

PowerPhotonic Ltd. was formed in 2004 to commercialize the technology from fundamental research undertaken at the world renowned Institute of Photonics and Quantum Sciences at Heriot-Watt University in Edinburgh. With operations in the United Kingdom and North America, we are well positioned to support companies across the globe.

The PowerPhotonic manufacturing process is based on a laser system that shapes and then smooths the refractive surface of fused silica glass. This gives us unprecedented flexibility to create a complete range of standard products including slow and fast axis collimators, lens arrays, beam shapers, transformers and correctors, as well as offering a cost effective custom micro-optics design service called LightForge™.