PRODUCTS

Optical Communication Applicat

-

Active Component Manufacturing

- Optical LD & PD Wafer

- Aspherical Lens and Cap

- TEC Device

- 2.5G-10G APD CHIP

- 10G PIN PD CHIP

- Transimpedance Amplifier

- Aluminum Nitride Substrates

- Alumina substrates

- High Temperature Co-fired Substrates (HTCC)

- 10G CWDM DFB Chip

- Microlens Array

- Smile Corrector

- Slow Axis Collimators(SAC)

- Fast Axis Collimators Arrays(FACA)

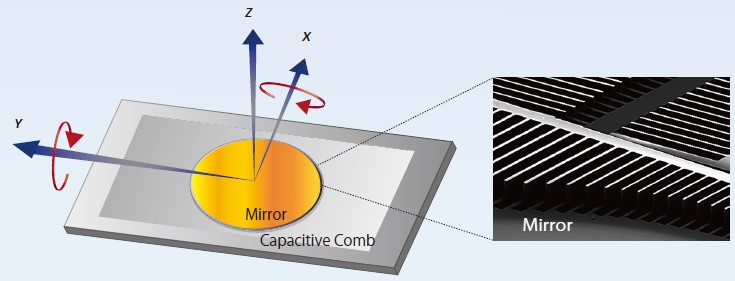

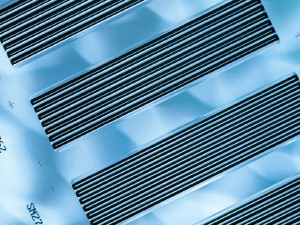

- MEMS Mirror

- SOI Wafers

- Super-thick Thermal Oxidized Wafers

- 25G DFB Laser Diode Chip

-

Test and Measurement

-

High Speed Qptical Transceiver

-

Optical Transport Network Devi

-

Network, Security and Delivery

-

Optical Automation Equipments

-

Passive Component Manufacturin

Industrial Laser and Optical A

-

Lasers

-

Laser Drivers

-

Controller Electronics

-

Optical Components

-

Materials

Solutions

-

BOSA Manufacturing and Packagi

-

ECDL Stable Laser Solution

-

Laser Spectroscopy Solution

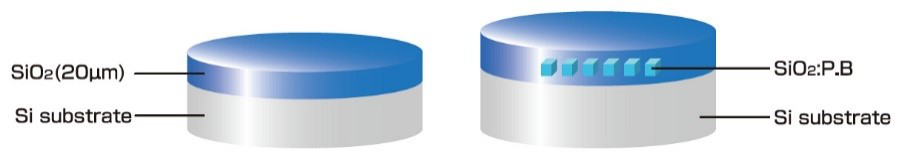

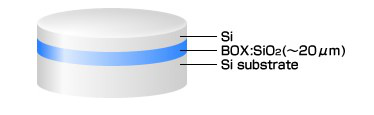

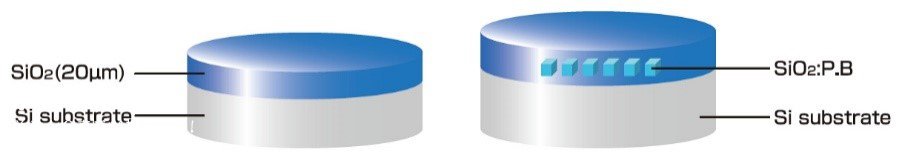

Super-thick Thermal Oxidized Wafers

With respect to optical waveguides (AWG), the so-called undercladding layer, which is the lowermost SiO2 film, has a critical effect on the process yield.

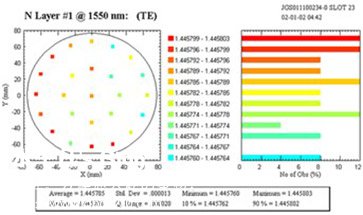

Guaranteed specifications

| Item | Specification |

| Film thickness | 20um±5%(Maximum thickness) |

In-plane uniformity | ±0.5% |

Surface uniformity | ±0.5% |

Refractive index(@1550nm) | 1.4458±0.0001 |

Refractive index plane distribution data

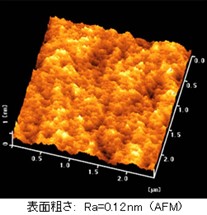

Surface roughness data

Supplier

KST service as a wafer foundry providing various services to deposit films on silicon wafers meeting customers’ needs since the establishment of 1998 throughout. Our deposition process service include oxide film, which enjoys the highest demand in the industry today ,and nitride film. In addition, we respond to the diverse needs of customers by creating films of different thickness, from common thin films to thick ones.